Fracturing nozzle is the key component of hydraulic jet fracturing tool for sandblasting and perforating. It is widely used for fracturing low permeability reservoir well, old well stimulation, shale gas horizontal wells layered and segmented fracturing.

Tungsten carbide nozzle,fracturing nozzle

Tungsten carbide (also called widia),due to its special physical properties,the potential applications for it is endless. Especially for wear parts.Tungsten carbide is an extremely hard material, almost as hard as diamond. Its high hardness, 700 to 2000

Hv30 (84-94 RA), together with its resistance to extreme temperatures, corrosion and abrasion makes it invaluable in many industrial and engineering applications where it is used to increase component wear life.

Tungsten carbide fracturing nozzle is the key component of hydraulic jet fracturing tool for sandblasting and perforating. It is widely used for fracturing low permeability reservoir well, old well stimulation, shale gas horizontal wells layered and segmented fracturing.

Except fracturing nozzle,we’ve listed below others of the components prone to wear that we make to order in tungsten carbide (widia). This list is meant to give you an indication of our capabilities and is certainly not exhaustive:

Rotary burr

Saw blades

Rollers

Rods and bars

Strips and plates

Mechanical seals

Grinding Jars and balls

Crusher tips and jaws(jaw crusher plates)

Bushings and sleeves

Rotors and stators

Mushroom head

Nozzles for oil pump

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.

Don’t hesitate to contact us if you want to explore the option of using a tungsten carbide alternative to replace a specific component. We supply 100% customized parts made to the supplied specifications. In the process, we recommend the appropriate tungsten carbide grade for each application.

Grades option of tungsten carbide

Usually,we have below grades for your choosing,if you have special needs, please contact us for more details.

Grades | Hardness (HRA) | Density (g/cm3) | T.R.S. (N/mm2) | ISO |

| YG6 | ≥91 | 14.9 | ≥1900 | K20 |

| YG6A | ≥92 | 14.9 | ≥1810 | K10 |

| YG6X | ≥91.5 | 14.9 | ≥1860 | K10 |

| YG8 | ≥90 | 14.8 | ≥2080 | K20 |

| YG8C | ≥89 | 14.8 | ≥2020 | K25 |

| YG10 | ≥88.5 | 14.3 | ≥2300 | K40 |

| YG10X | ≥92 | 14.45 | ≥3400 | K40 |

| YG15 | ≥87 | 13.9 | ≥2580 | K40 |

| YG20 | ≥85.5 | 13.5 | ≥2750 | K40 |

| YG20C | ≥84.5 | 13.5 | ≥3000 | K40 |

| YS2T | ≥92 | 14.4 | ≥2500 | M20 |

| YL10.2 | ≥91.5 | 14.5 | ≥3100 | K20-K30 |

| YN6 | ≥88.5 | 14.5 | ≥1800 | |

| YN8 | ≥87.5 | 14.3 | ≥2000 |

E-mail: sales@ztcarbide.com

Add: No.1 of Longxin international building, No.255 of Tongxia Road,Shi Feng District, Zhuzhou Hunan Province,China

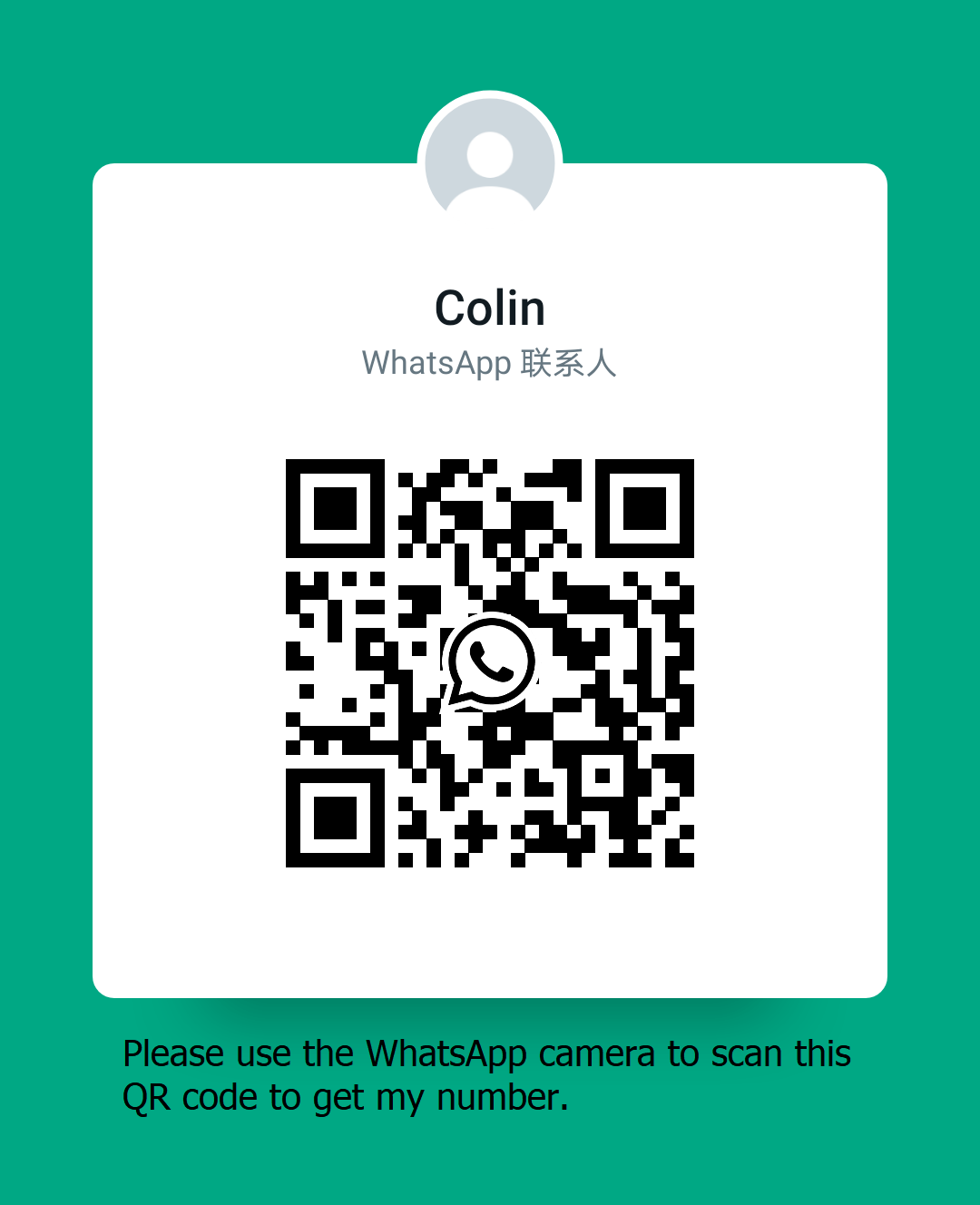

We chat